Navigating the Globe of Fasteners and Machining: Techniques for Accuracy and Rate

In the elaborate world of fasteners and machining, the quest for accuracy and rate is a continuous obstacle that demands meticulous focus to detail and strategic planning. From recognizing the varied variety of fastener kinds to choosing ideal products that can stand up to rigorous demands, each action in the procedure plays a critical function in accomplishing the wanted outcome. Precision machining techniques further raise the complexity of this craft, needing a delicate equilibrium in between technical expertise and cutting-edge methods. As we dive into the methods that can enhance both rate and effectiveness in this domain name, the interaction between quality assurance actions and functional excellence becomes a critical centerpiece.

Understanding Fastener Kind

When picking bolts for a project, comprehending the different types offered is important for making certain optimum efficiency and integrity. Fasteners can be found in a variety of kinds, each developed for details applications and requirements. Screws are used with nuts to hold materials with each other, while screws are functional fasteners that can be made use of with or without a nut, relying on the application. Nuts, on the various other hand, are internally threaded bolts that friend with bolts or screws, giving a safe and secure hold. Washers are vital for dispersing the load of the bolt and preventing damages to the product being secured. Additionally, rivets are permanent bolts that are suitable for applications where disassembly is not needed. Comprehending the distinctions in between these fastener kinds is important for choosing the right one for the job, making certain that the connection is solid, long lasting, and reputable. By picking the suitable fastener type, you can optimize the performance and long life of your task - Fasteners and Machining.

Choosing the Right Materials

Understanding the significance of picking the appropriate products is critical in guaranteeing the optimal performance and dependability of the selected fastener kinds went over formerly. When it pertains to bolts and machining applications, the material option plays an essential duty in figuring out the general stamina, sturdiness, rust resistance, and compatibility with the desired atmosphere. Various materials supply differing properties that can considerably influence the performance of the bolts.

Typical materials used for bolts include steel, stainless steel, brass, aluminum, and titanium, each having its distinct strengths and weaknesses. Steel is renowned for its high stamina and durability, making it appropriate for a large range of applications. Picking the best material includes considering aspects such as stamina demands, ecological problems, and spending plan constraints to make sure the desired efficiency and long life of the fasteners.

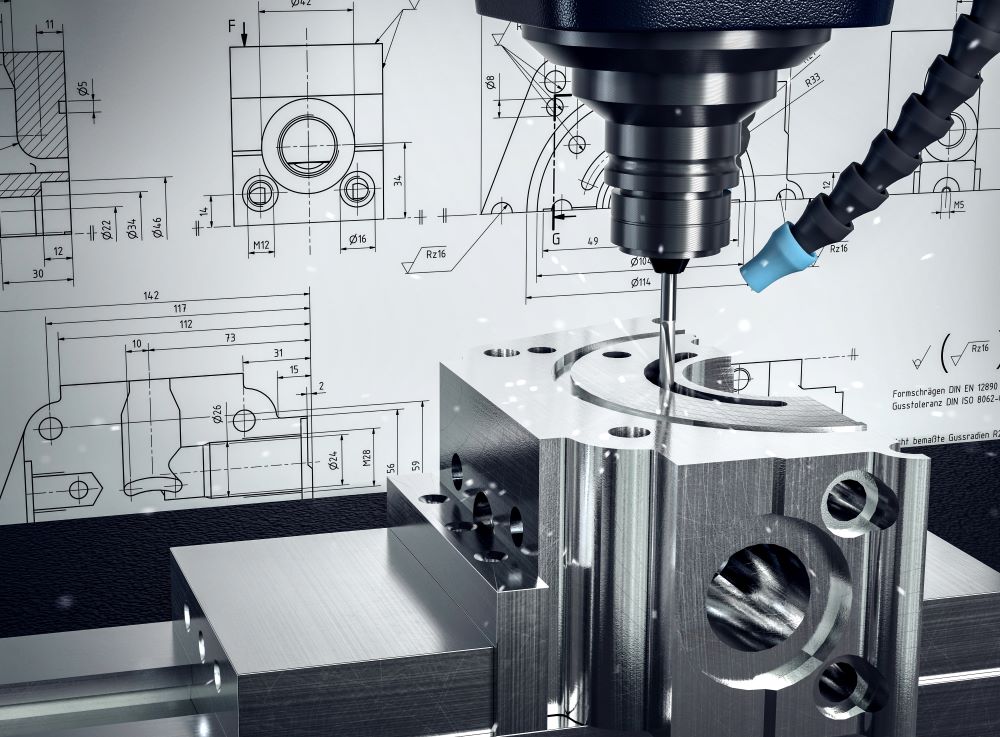

Precision Machining Techniques

In enhancement to CNC machining, other accuracy techniques like grinding, transforming, milling, and drilling play essential duties in bolt production. Grinding aids attain great surface area coatings and limited dimensional resistances, while transforming is typically made use of to produce cylindrical components with exact sizes. Milling and boring procedures are essential for forming and developing openings in bolts, ensuring they satisfy precise requirements and function correctly.

Enhancing Rate and Efficiency

To optimize fastener manufacturing processes, it is vital to improve you could try here procedures and execute reliable methods that enhance accuracy machining techniques. One vital technique for boosting speed and effectiveness is the execution of lean production concepts. By reducing waste and focusing on continuous improvement, lean techniques help eliminate traffic jams and enhance workflow. Additionally, spending in automation innovations can considerably enhance production rate. Automated systems can take care of repetitive jobs with precision and rate, allowing employees to concentrate on more facility and value-added tasks. Taking On Just-In-Time (JIT) inventory management can additionally boost efficiency by making certain that the appropriate products are offered at the correct time, decreasing excess supply and lowering preparations. In addition, fostering a culture of partnership and interaction amongst employee can enhance total efficiency by promoting transparency, analytic, and development. By combining these methods, makers can attain a balance in between speed and precision, eventually enhancing their one-upmanship in the bolt market.

Quality Assurance Actions

Carrying out rigorous quality assurance browse around this web-site steps is crucial in ensuring the dependability and uniformity of fastener items in the production procedure. Quality assurance procedures include numerous stages, beginning with the choice of resources to the last examination of the completed fasteners. One fundamental aspect of quality assurance is conducting detailed product inspections to confirm compliance with requirements. This entails analyzing factors such as product longevity, structure, and stamina to ensure that the bolts meet market criteria. Furthermore, keeping track of the machining processes is essential to support dimensional precision and surface area finish quality. Making use of sophisticated modern technology, such as computerized inspection systems and precision measuring devices, can improve the precision and performance of quality assurance treatments.

Normal calibration of equipment and equipment is vital to preserve consistency in manufacturing and guarantee that fasteners satisfy the needed tolerances. Carrying out strict methods for determining and attending to issues or non-conformities is important in protecting against substandard products from getting in the marketplace. By developing a thorough top quality control structure, suppliers can promote the online reputation of their brand name and supply bolts that link satisfy the highest requirements of efficiency and durability.

Conclusion

In the complex realm of fasteners and machining, the mission for accuracy and rate is a continuous difficulty that requires thorough interest to information and calculated planning. When it comes to fasteners and machining applications, the product selection plays a vital role in identifying the general toughness, sturdiness, rust resistance, and compatibility with the intended atmosphere. Precision machining entails numerous advanced techniques that make certain the tight resistances and requirements needed for fasteners.In enhancement to CNC machining, various other accuracy strategies like grinding, transforming, milling, and exploration play crucial functions in bolt manufacturing.To enhance bolt production procedures, it is vital to enhance operations and implement efficient strategies that complement precision machining strategies.